Q: How safe are your hand pallet trucks? A: You might well be breaking the law!

Does your company use hand pallet trucks? If so, you could easily be falling foul of the law… Independent research suggests that moving a load of just 500kg could put you the wrong side of official guidelines. Worse still, government figures confirm that anyone using a hand pallet truck runs a much greater risk of injury than previously thought.

In this short report we will:

- explain the legislation.

- reveal shocking research findings on operator stress levels

- give you valuable tips on staying safe and legal

- help you choose the right equipment for your location

Your responsibilities as an employer

Let’s start with your responsibilities. If you’re an employer, it is your responsibility to do everything reasonable to maintain the well-being of your employees. In the case of lifting and shifting heavy loads, that means making sure you provide the right equipment and training.

Importantly, this doesn’t simply mean avoiding one-off incidents or injuries (the kind you might expect from moving an unusually heavy load). You need to be aware of the gradual and cumulative effect of heavy lifting on a worker’s musculoskeletal system…. and the damage such injuries can do to the smooth running of your business.

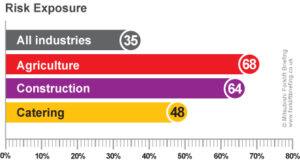

Workers exposed to the risk of carrying or moving heavy loads for at least a quarter of their working time. (Source: 4th European Working Conditions Survey – 2005)

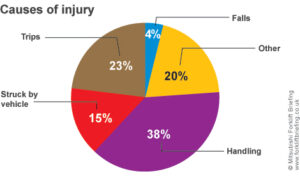

According to the HSE, the UK agency for Health and Safety, more than one third of all injuries requiring at least three days off from work are caused by manual handling (lifting, lowering, pushing, pulling or carrying). On average, each sufferer took 20 days off in a 12-month period – which represents a massive inconvenience to your operations and a blow to your productivity.

How does this apply to hand pallet trucks?

Put simply, if you are moving loads frequently – or shifting any loads greater than 500kg – you should be strongly considering trading in your hand pallet truck for a battery-powered version. In the first of these scenarios, it is the cumulative strain that needs to be avoided. In the case of heavy loads, it is the effort involved in starting and stopping a load – and keeping it in motion – that is the key issue.

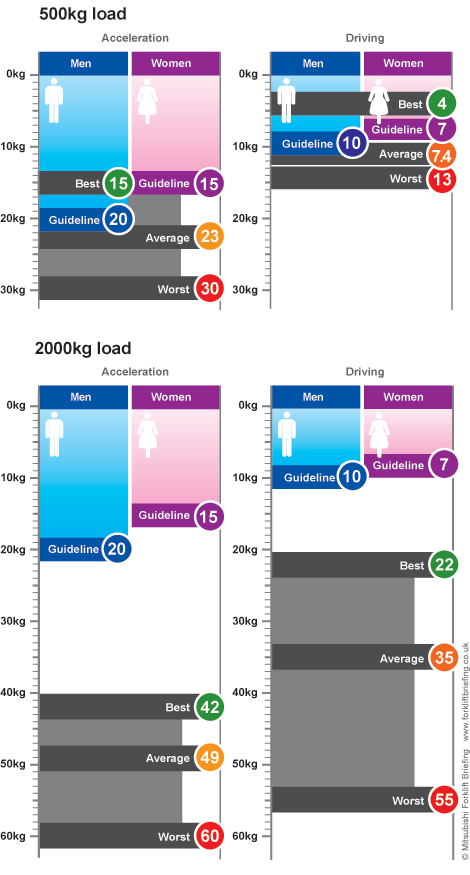

The official guideline figure for starting or stopping a load is about 20kg for men (typically the maximum weight for a suitcase at an airport check-in before you pay for excess baggage) or 15kg for women. The acceptable figure for keeping a load in motion is 10kg for men and about 7kg for women. But how does that work in practice?

How much effort is needed to use a hand pallet truck?

Independent researchers tested 17 different makes of hand pallet trucks in order to obtain an accurate average across a wide range of manufacturers moving loads of 500kg and 2000kg.

The results were conclusive – and shocking.

Starting a 500kg load from stationary takes, on average, an effort of 23.3kg. Increase the load to 2000kg (2 tonne) and the force required is 49.6kg – massively greater than the official guidelines mentioned earlier.

Raising a 2000kg load on a pallet truck is also very demanding – it taken an average force of 35.1 kg (again much higher than the guideline). Even keeping a 2 tonne load in motion – at 30.7kg – exceeds the guidelines by a whopping 53.3%.

Danger in the lorry

Operating hand pallet trucks in the confines of a lorry (and its hydraulic lifting platform) requires careful consideration. While keeping an average 700kg load in motion demands up to 18kg of force – 80% more than guidelines – stopping that same mass on the hydraulic lift platform requires nearly twice the effort.

Exposure to rain water increases this risk further. For maximum control, we recommend fitting the hand pallet truck with a rubber steering wheel and a manual brake.

What should I look for in a battery powered pallet truck?

It makes sense to purchase a reputable brand. Not only is the build quality likely to be superior but the dealer supplying you the equipment will be able to advise you on the appropriate capacity and the best type of wheels for your particular application. For example, softer tyres are better for slippery conditions but wear more quickly. Composites such as Vulkollan make a great general purpose tyre which is very durable.

- Desirable features include:

- A tiller arm that always returns smoothly to the upright position

- A brake bypass function – allowing creep speed operations with tiller arm in upright position

- Linked castor wheels – for maximum stability even with high loads and on sharp turns

- Generous lifting height – this can prove very useful on ramps and loading docks, especially with damaged pallets

- Easily-switched performance modes (can be instantly changed to suit the driver’s ability and the operating conditions)

- A ‘closed’ chassis (to prevent water and dirt getting into the inside of the truck – fewer repairs, longer working life and lower running costs)

- Heavy duty forks (greater durability)

- Oil-filled transmission (quiet running, reliable and low maintenance)

- Electronic pump control (smoother and quieter than old-fashioned contactors)

If you would like an assessment of whether you should be switching to a powered pallet truck… and advice on the correct specification, please click here

The conclusion

Unless you can reduce the size of each load – to 500kg or less – whilst also minimising the number of operations – the only realistic (and legal) option is to mechanise the handling process by switching from a hand pallet truck to a battery electric power pallet truck.

The big bonus is that you’ll increase the speed of the operation and reduce the risk of time off from health problems such as lower back pain.

Source: https://forkliftbriefing.com/work-safely/are-hand-pallet-trucks-putting-your-business-at-risk/